Mechatronic Assemblies & Contract Manufacturing

With Local Advantages & Decades of Experience

Full-Service Contract Manufacturing

When it comes to manufacturing mechatronic assemblies, we are your reliable partner. Our offering goes beyond high-quality contract manufacturing - we provide comprehensive technical expertise, from development to mass production.

Why Manufacture with SEIDEL?

- Strong Customer Focus & individual support

- International Management & Access to Local Supply

- ISO 9001 certified since 2016

- Two production sites of over 4000 m² manufacturing space for maximum efficiency.

- Strict Quality Control & High Standards

- Vertical Integration & Multi-Skill Expertise

- In-house Manufacturing & Assembly

- Expertise in Moulding for Small and Large Production Runs

- Support from small series production to mass production

A. Vertically Integrated Solutions

Our comprehensive manufacturing services cover every step—from production and testing to the delivery of your products—always tailored to your specific requirements. Whether you are developing a completely new product or already have a design concept, we support you from the initial idea to mass production. We provide manufacturing services for companies seeking a reliable production solution, from small series to large-scale production. Our experienced engineers analyze your specifications and requirements in detail to deliver a market-ready product of the highest quality.

B. Manufacturing Solutions

With decades of experience in contract manufacturing, we provide tailored production solutions that ensure the highest quality, on-time delivery, and optimal efficiency. Our customers benefit from a streamlined, well-structured manufacturing process that saves them time and resources.

Leveraging our extensive expertise in manufacturing and assembly, we successfully execute even the most demanding projects with precision and reliability. In our state-of-the-art production facilities, we manufacture machines, systems, and components with the highest level of accuracy—ranging from small series to large-scale production.

C. Design-And-Build Service

Not all designs or prototypes are fully ready for production, but we can help you with that. Our engineering team assists with updating designs, specializes in the initial development and assists in the early stages of production and modifies design for manufacturing and assembly. Our engineers have years of experience in:

- ⮚ Updating CAD model

- ⮚ Preparing Production Packages

- ⮚ Developing test procedures

- ⮚ Documentation

Contract Manufacturing Experience

We have been active in the contract manufacturing industry for over 15 years and have extensive experience in overcoming challenges that can arise in any production environment.

Throughout this time, we have had the privilege of working with some of the most demanding clients. This opportunity has been made possible by the expertise we have gained through our collaborations. Our experience has enabled us to develop strong competencies to ensure a seamless production cycle for our customers.

We have successfully established ourselves in the following industries:

- Automotive Industry

- Manufacturing Industry

- Medical Industry

- IOT & Building Automation

Intellectual Property (IP) Protection

D. Protecting Your Business Assets

As a German company operating internationally, we are particularly sensitive to intellectual property (IP) concerns.

We safeguard all intellectual property rights that arise within our facilities. All IP rights remain the property of our clients, backed by binding non-disclosure agreements that cover all our customer relationships.

Through strict information handling and management practices, we ensure the highest level of protection for your interests.

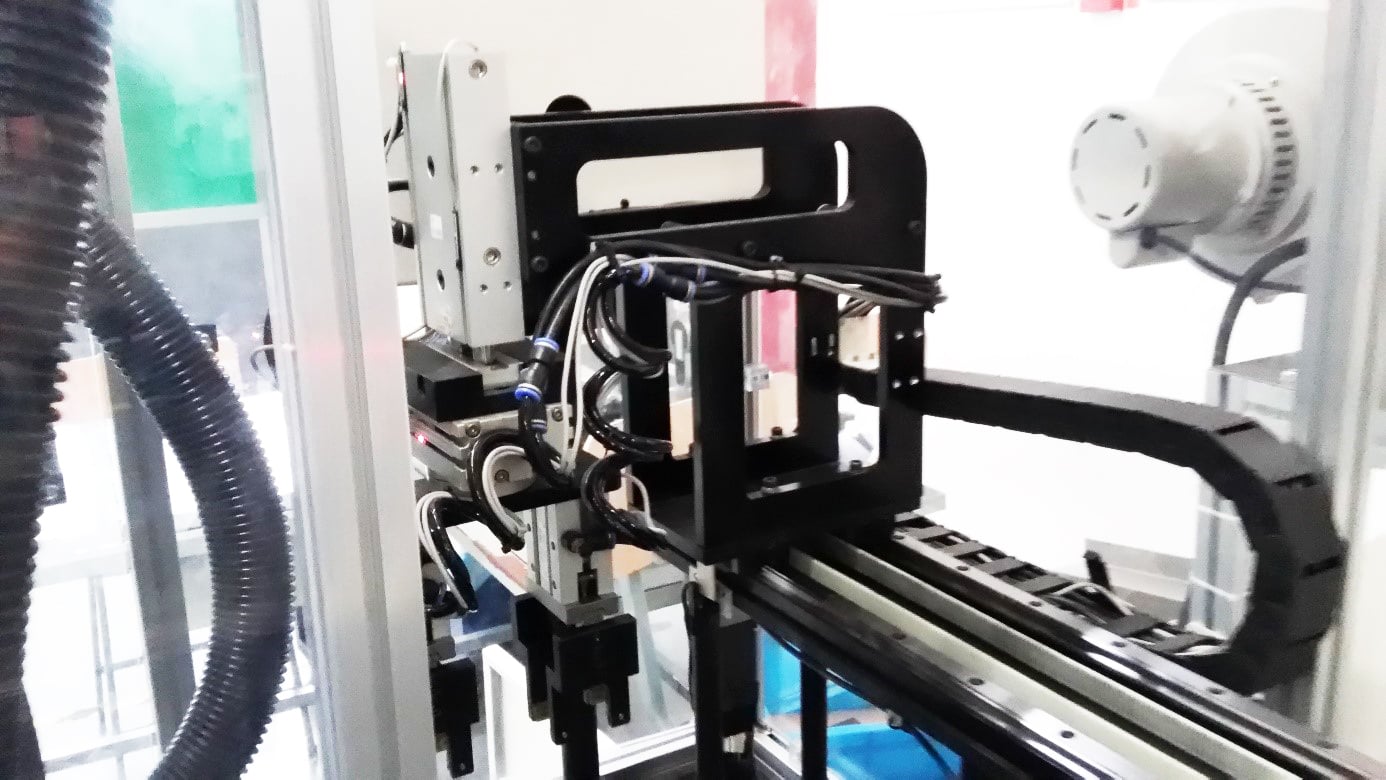

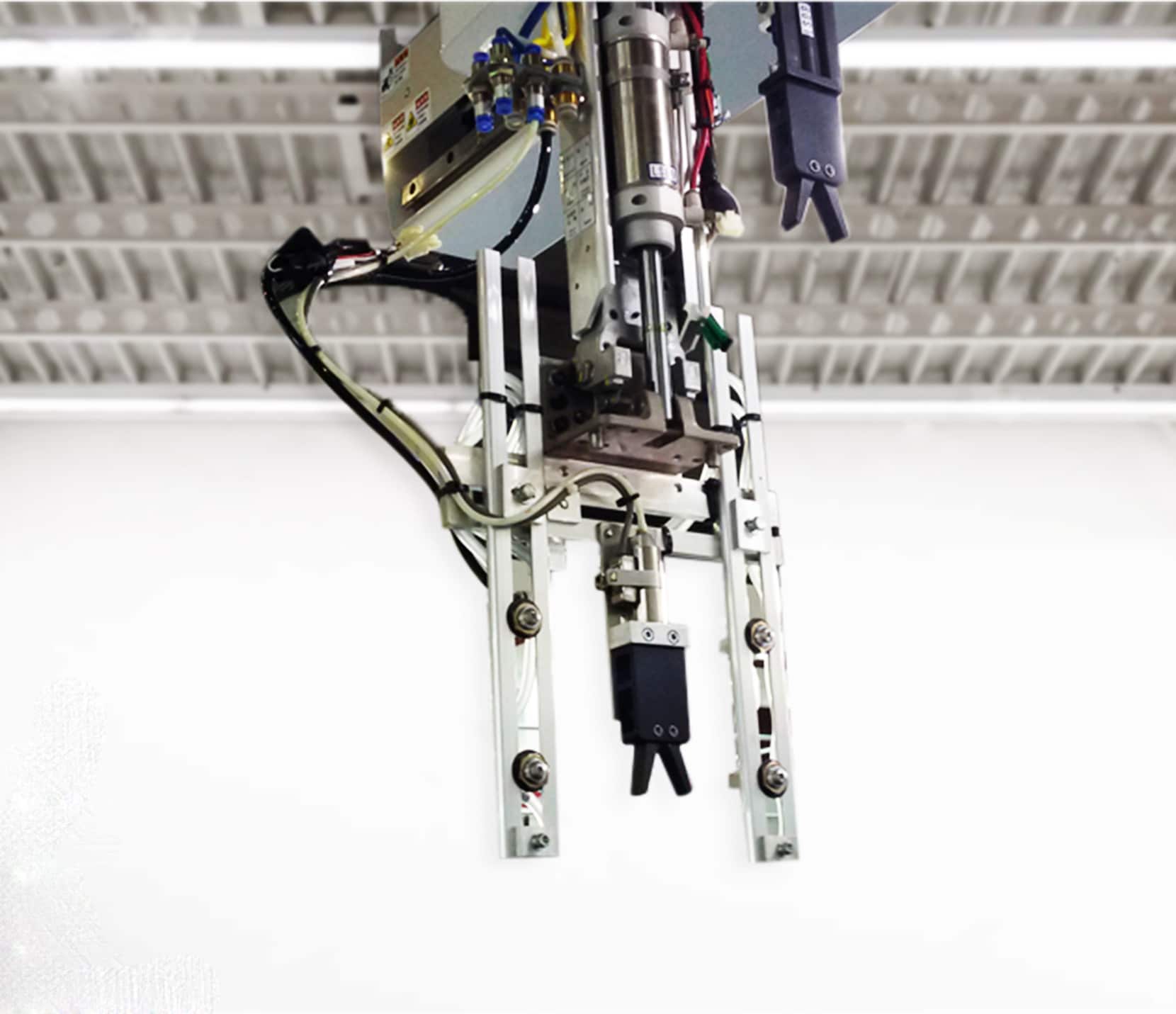

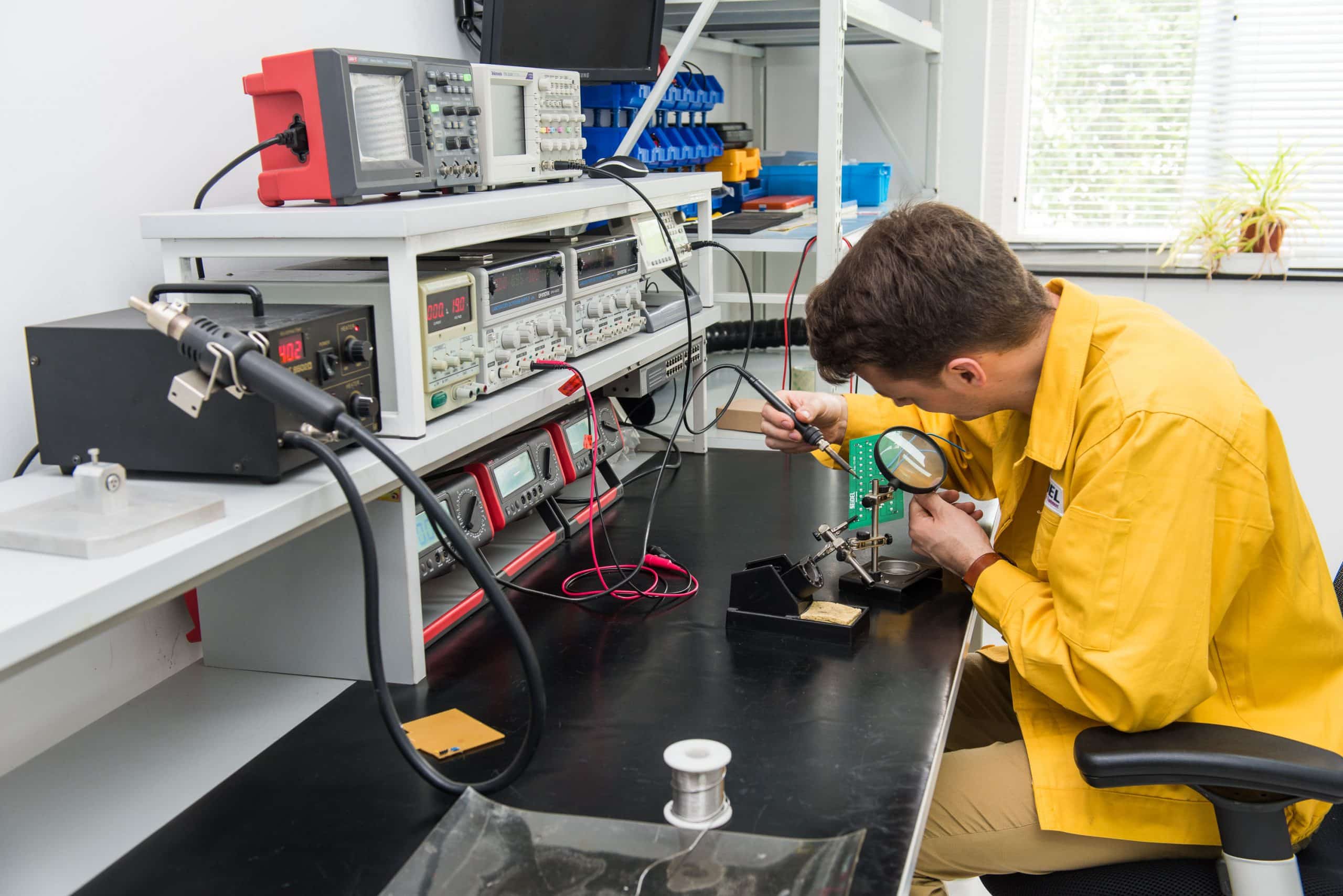

Assembly & Integration

E. Great Assembly Techniques for Low and Mid Volume Integration

With deep product understanding as a developer and the advantage of our strategic supply chain position, we offer assembly services for small series and module production.

Our years of experience in assembly have shown us the importance of flawless prototypes, bill of materials, and work instructions. The process of manufacturing a single machine differs significantly from producing hundreds of identical models, requiring meticulous planning to ensure repeatability and consistency every time.

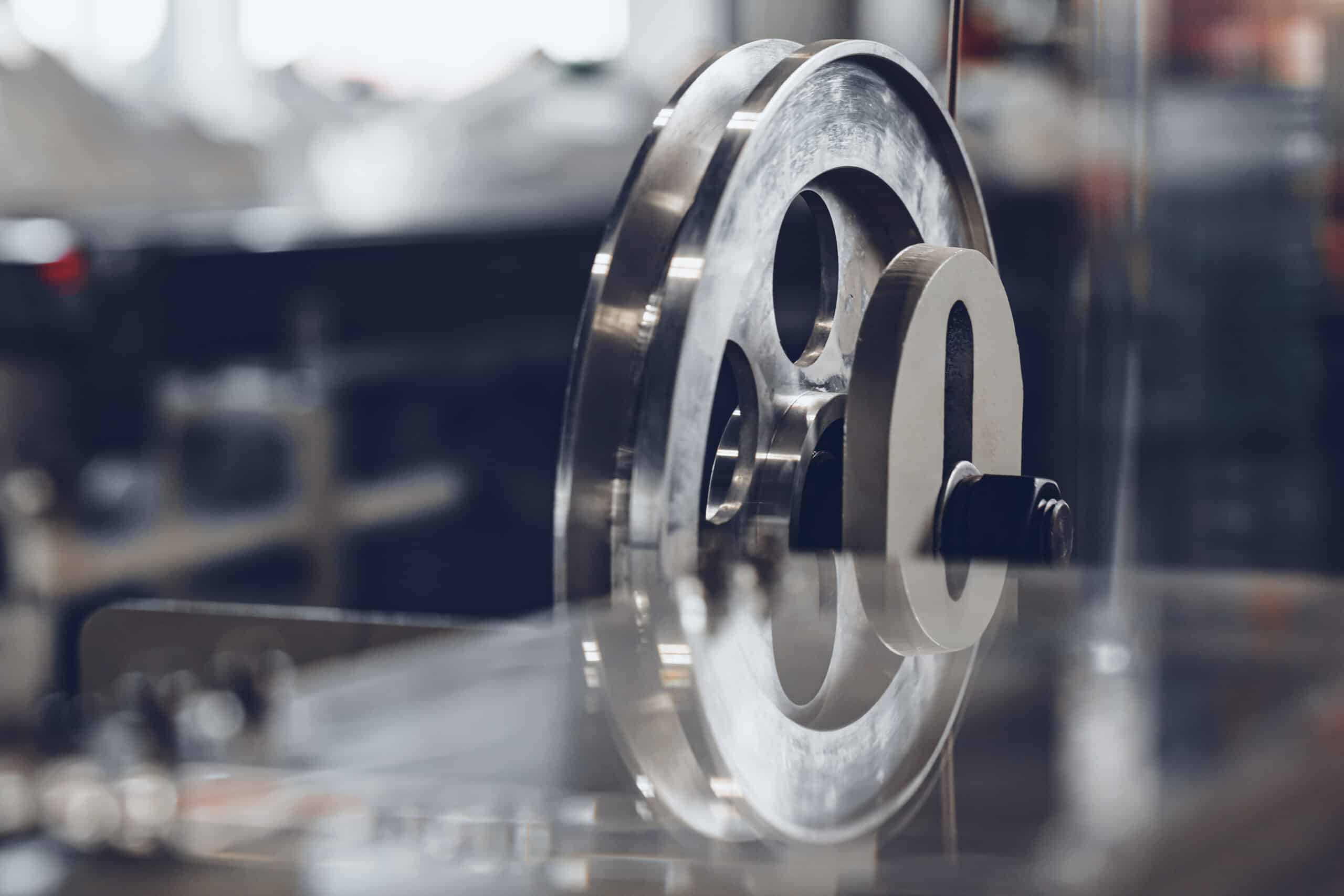

Component Fabrication

F. In-House Manufacturing

We quickly realized that outsourcing individual or low-volume parts is not an option in an environment where everyone is looking for large quantities. In order to maintain the highest quality and reliability of our machines, and to have excellent control over cost, quality, lead time and efficiency, we had to install our own in-house component manufacturing capabilities.

Today, we are pleased to offer our customers an extensive list of in-house capabilities. Not only does this set us apart from other contract manufacturing companies, but it also allows us to provide our customers with a complete solution for their manufacturing needs, from start to finish.

We stand out by our ability to do the following, in-house:

- Precision CNC Machining

- CNC Milling

- CNC Turning

- Aluminium CNC Machining

- Prototype CNC Machining

- Drilling, Spotting, & Boring

- Shot Blasting, deburring, Laser engraving

- Bending, welding, and prototyping

- Plastic Injection, Electronic Lab & More

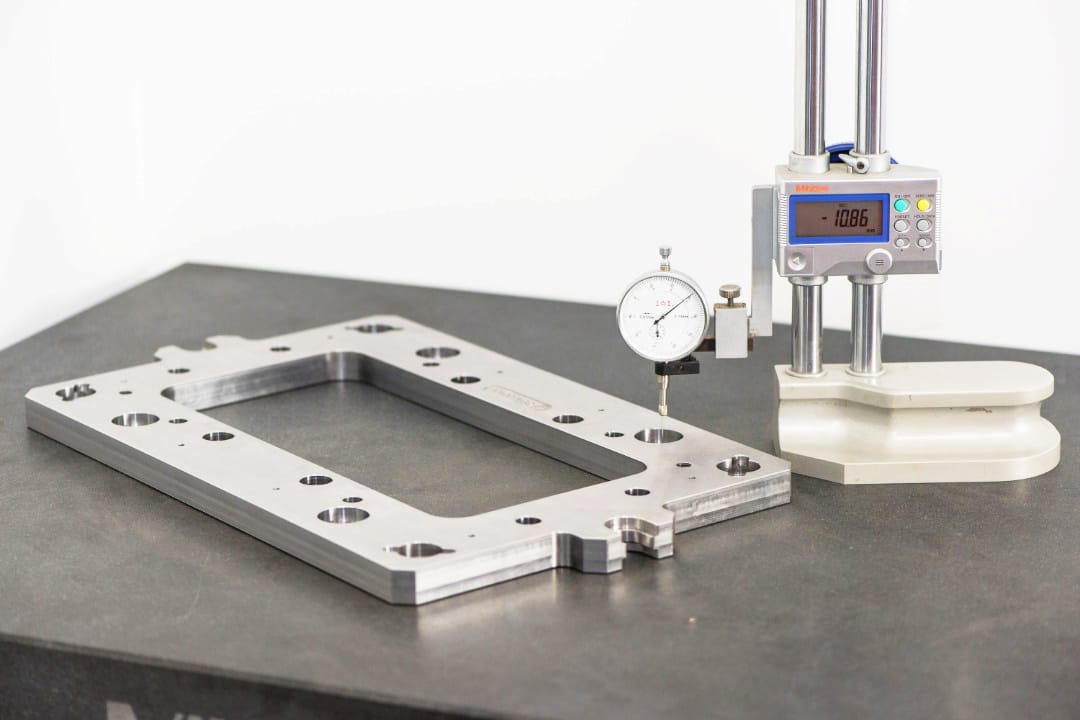

Quality Control

F. Quality Systems

Quality assurance is one of our core competencies. Our process-oriented quality management system covers every stage—from initial product design and development to program management and manufacturing.

We have implemented rigorous quality assurance measures to meet a wide range of customer and regulatory requirements across our operations. All our products and machines are delivered with complete documentation and thorough inspection controls to ensure the highest standards.