Mechatronische Baugruppen & Auftragsfertigung

- mit Standortvorteilen & jahrzehntelanger Erfahrung

Fertigung durch SEIDEL

Wenn es um die Fertigung mechatronischer Baugruppen geht, sind wir Ihr verlässlicher Partner. Unser Angebot umfasst nicht nur hochwertige Lohnfertigung, sondern auch umfassendes technisches Know-how – von der Entwicklung bis zur Serienproduktion.

Warum fertigen durch SEIDEL?

Erfahrung & Qualität – Seit 2016 ISO 9001 zertifiziert, mit über 70 qualifizierten Mitarbeitern.

Optimierte Prozesse – Zwei Fertigungsstandorte mit 4.000 m² Produktionsfläche für maximale Effizienz.

Kosteneffiziente Lösungen – Durch deutsches Produktions-Know-how und langjährige Standorterfahrung fertigen wir Teil- und Komplettbaugruppen wirtschaftlich und zuverlässig.

Individuelle Unterstützung – Unser erfahrenes Ingenieursteam begleitet Sie in jeder Phase – von der Entwicklung über die Prototypenfertigung bis zur Serienproduktion.

Wir optimieren Ihre Entwürfe gezielt für den Fertigungsprozess, reduzieren Kosten und minimieren Vorlaufzeiten – egal, ob für Kleinserien oder Großproduktionen.

Lassen Sie uns gemeinsam Ihre Projekte effizient und erfolgreich realisieren!

Full-Service

- Herstellung von komplexen und einfachen Maschinen

- Starke Kundenorientierung

- Strenge Qualitätskontrolle & hohe Ansprüche

- Vertikale Integration und Kombination mehrerer Kompetenzen

- Eigene Herstellung und Montage

- Internationales Management & Zugriff auf die lokale Lieferkette

- Kompetenz im Werkzeugbau für kleine & große Stückzahlen

- Produktentwicklung, Produktverbesserung und Produktionsoptimierung

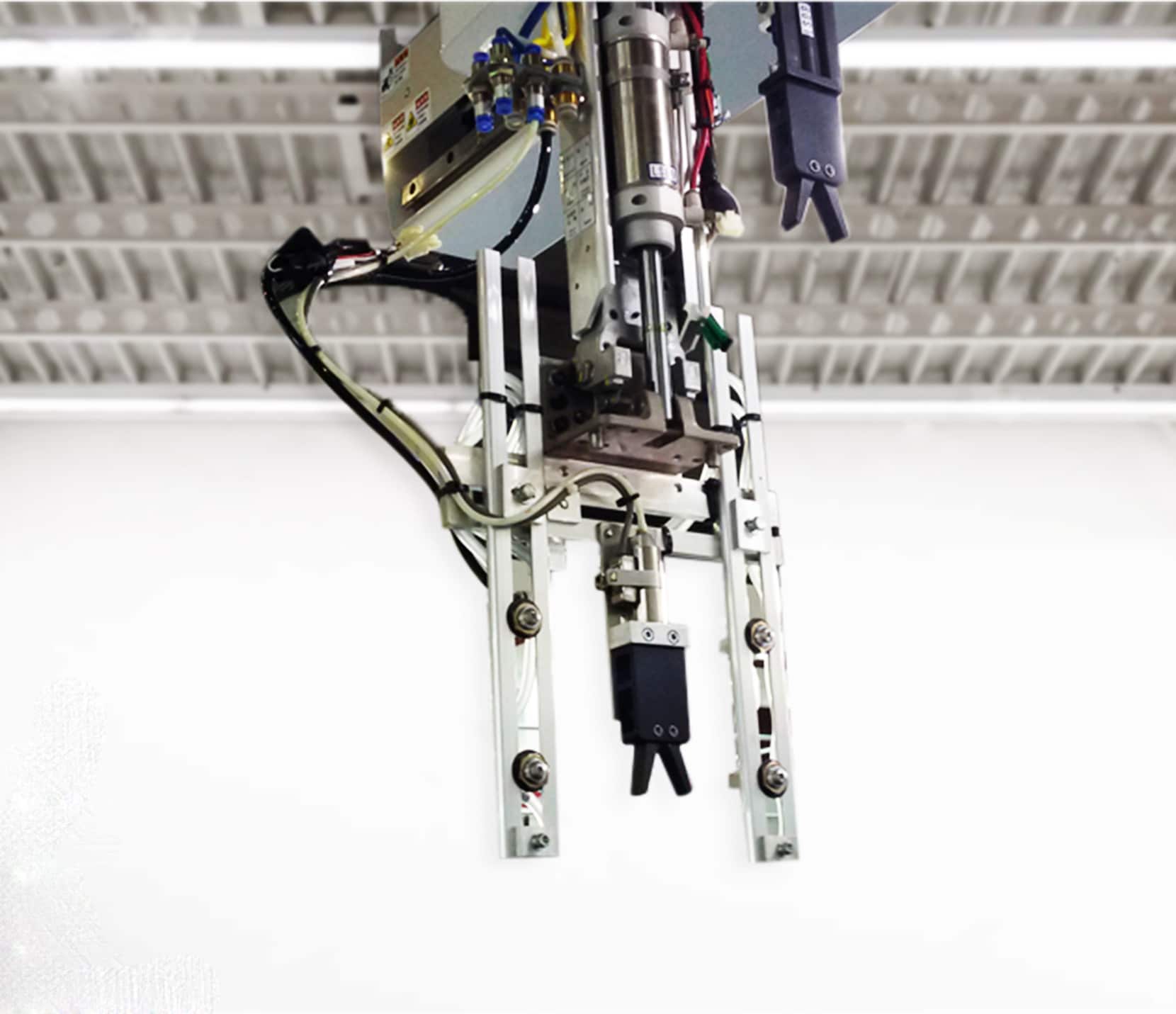

A. Vertikal Integrierte Produktionslösungen

Unsere umfassenden Fertigungsdienstleistungen decken sämtliche Schritte ab – von der Herstellung über die Prüfung bis hin zur Auslieferung Ihrer Produkte, stets gemäß Ihren spezifischen Anforderungen. Egal, ob Sie ein völlig neues Produkt entwickeln oder bereits eine Designidee haben – wir unterstützen Sie von der ersten Konzeptphase bis zur Serienproduktion. Wir bieten Fertigungsdienstleistungen für Unternehmen, die eine zuverlässige Lösung für ihre Produktion suchen – von Kleinserien bis hin zur Massenfertigung. Unsere erfahrenen Ingenieure analysieren Ihre Spezifikationen und Anforderungen im Detail, um ein marktfähiges Produkt in höchster Qualität zu realisieren.

B. Fertigungslösungen

Sobald wir alle relevanten Informationen für die Produktion Ihres Produkts ermittelt haben, entwickeln wir einen maßgeschneiderten Fertigungsprozess, der höchste Qualität, termingerechte Lieferung und optimale Leistung sicherstellt. Bereits Hunderte von Projekten haben von unserer schlüsselfertigen Lohnfertigung profitiert.

Unsere Ingenieure verfügen über das Fachwissen, um das volle Potenzial Ihres Produkts bei der Herstellung und Montage auszuschöpfen. Das Ergebnis: Unsere Kunden erleben eine deutliche Reduzierung ihres Aufwands und können sich auf die wesentlichen Aspekte ihres Geschäfts konzentrieren. In unseren modernen Produktionsstätten entwickeln wir einen effizienten Fertigungsplan für die Herstellung Ihrer Maschinen, Anlagen und Komponenten.

C. Produktweiterentwicklung zur Produktionsreife

Nicht alle Entwürfe oder Prototypen sind vollständig produktionsreif. Hier können wir Sie Unterstützen. Unser Ingenieurteam hilft bei der Überarbeitung des Designs, ist erfahren in der Weiterentwicklung und bringt Ihr Produkt ins Ziel. Auch der Entwurf für die Fertigung und Montage wird erstellt. Unsere Ingenieure verfügen über jahrelange Erfahrung in:

- Aktualisierung von CAD-Modellen

- Vorbereiten von Produktionspaketen

- Entwicklung von Prüfverfahren

- Dokumentation

Erfahrung in der Auftragsfertigung

Wir sind seit mehr als 15 Jahren in der Lohnfertigungsbranche tätig und verfügen über Erfahrung im Umgang mit Hindernissen, die innerhalb jeder Produktionsumgebung auftreten.

Dabei haben wir die Freude, mit einigen der anspruchsvollsten Kunden zusammenarbeiten zu dürfen. Diese Möglichkeit wurde durch die Qualifikationen geschaffen, die wir bei der Arbeit mit unseren Kunden erworben haben. Aufgrund unserer bisherigen Erfahrungen habe wir reichlich Kompetenzen gebildet, um einen reibungslosen Produktionszyklus für unsere Kunden zu gewährleisten.

In folgenden Branchen haben wir uns bereits erfolgreich bewährt:

- Fertigungsindustrie

- Medizinbranche

- Automobilindustrie

- IOT & Gebäudeautomatisierung

Intellectual Property (IP) Protection

D. Schutz Ihres Geistigen Eigentums

Als Deutsches Unternehmen im Ausland sind wir im Bezug auf IP (Geistiges Eigentum) besonders sensibilisiert.

Wir schützen sämtliche Rechte am geistigen Eigentum, die in unseren Räumlichkeiten entstehen. Alle geistigen Eigentumsrechte bleiben Eigentum unserer Kunden mit bindenden Geheimhaltungsvereinbarungen, die alle unsere Kundenbeziehungen abdecken.

Durch strickten Umgang mit Informationen und Managementpraktiken schützen Wir Ihre Interessen.

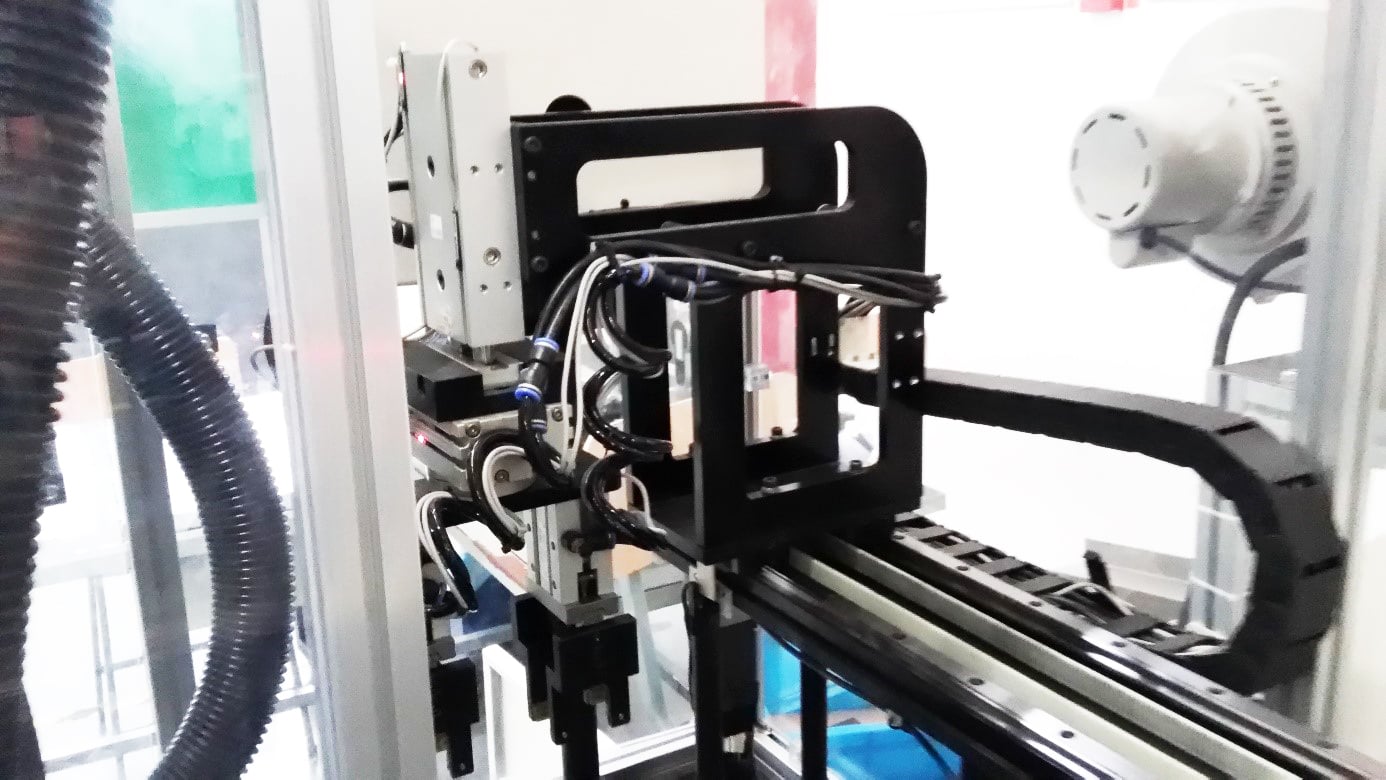

Montage & Integration

E. Montagetechniken für die Integration kleiner und mittlerer Stückzahlen

Als stiefgehendes Produktverständnis als Entwickler von Produkten & durch unserer vorteilhaften Lieferkettenlage, bieten wir die Montage von Kleinserien und Baugruppenproduktion an. Unsere langjährige Erfahrung in der Montage hat uns gezeigt, wie wichtig es ist, dass Muster, Stücklisten und Arbeitsanweisungen eines Entwurfs perfekt sind. Der Prozess zur Herstellung einer Maschine variiert drastisch im Vergleich zur Fertigung von Hunderten von Modellen derselben Maschine, um sicherzustellen, dass sie jedes Mal wiederholbar ist.

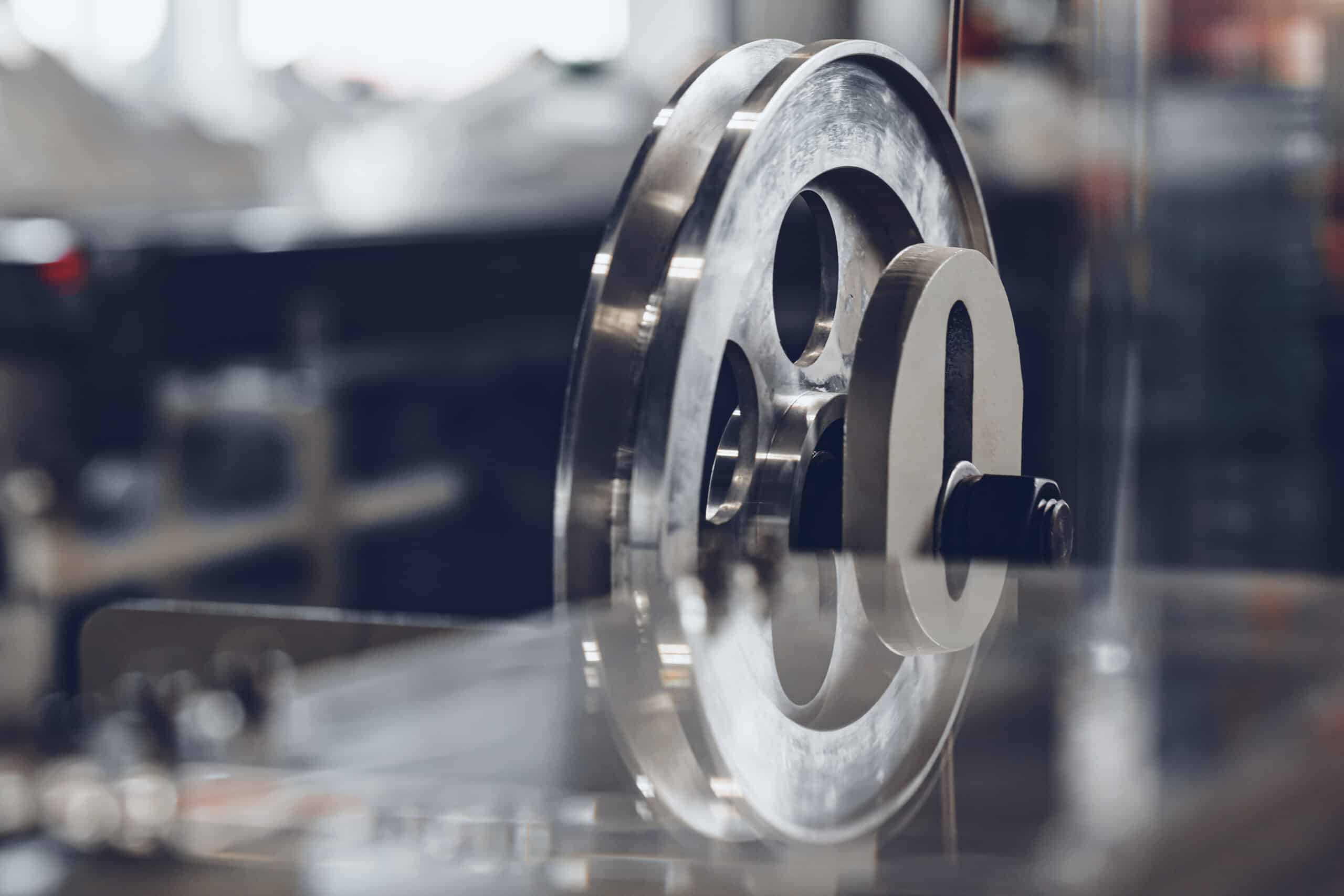

Herstellung von Bauteilen

F. Eigene Herstellung

Wir haben schnell erkannt, dass die Auslagerung von Kleinserien oder Einzelteilen in einem Umfeld, in dem jeder nach großen Mengen sucht, keine Option darstellt. Um höchste Qualität und Zuverlässigkeit unserer Maschinen zu gewährleisten und eine ausgezeichnete Kontrolle über Kosten und Lieferzeiten zu haben, mussten wir unsere eigenen Fertigungskapazitäten für Komponenten einrichten.

Heute bieten wir unseren Kunden, die sich auf Präzisionsbearbeitung in kleinen Stückzahlen konzentrieren, dieselben Dienstleistungen und Kenntnisse an.

Wir zeichnen uns dadurch aus, dass wir die folgenden internen Fertigungsprozesse anbieten können:

- CNC-Bearbeitung

- Fräsen

- Schweißen

- Stanzen

- Drehen

- Kugelstrahlen

- Biegung

- Lasergravur

- Kunststoffspritzguss

- Formenbau

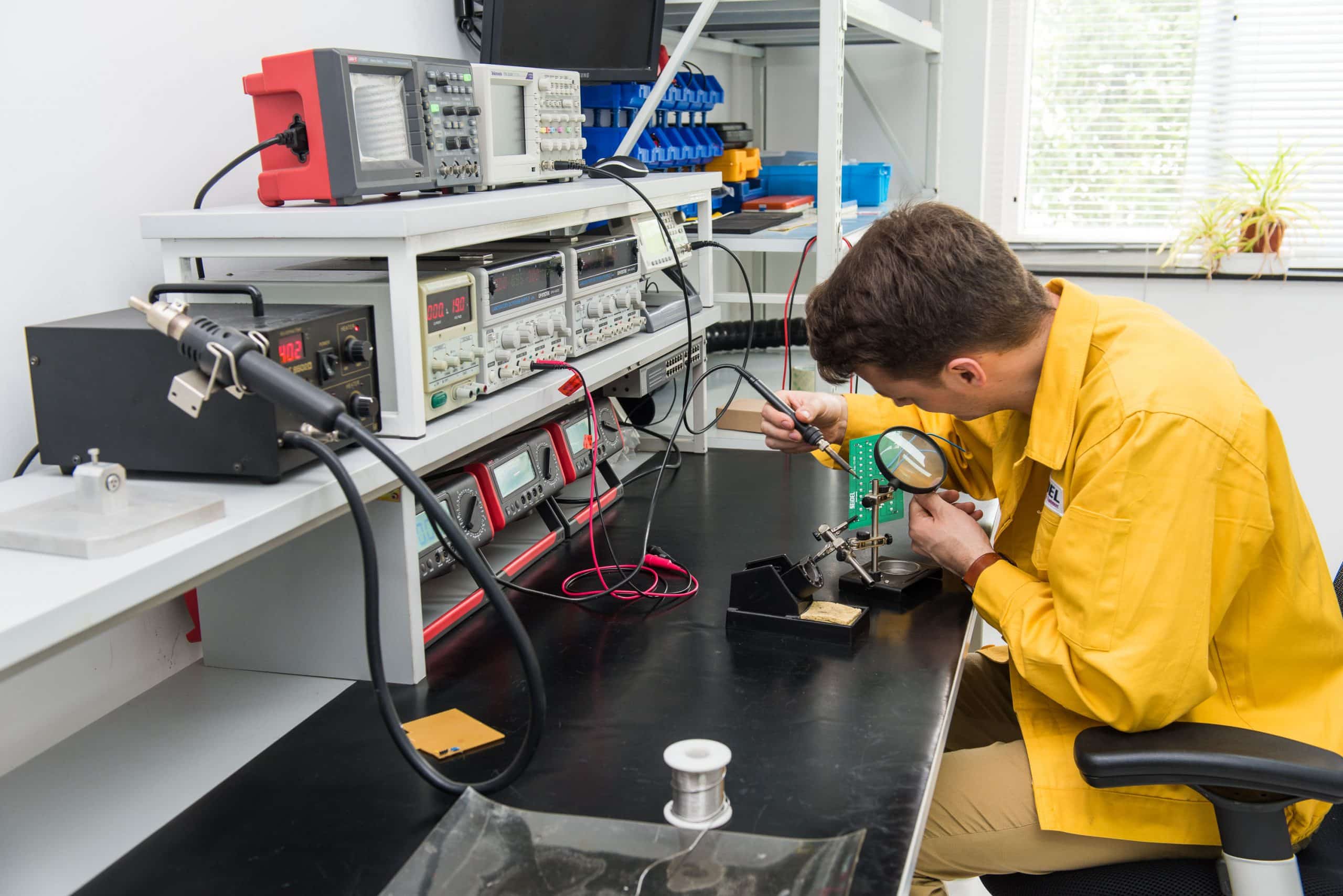

- Elektronisches Labor

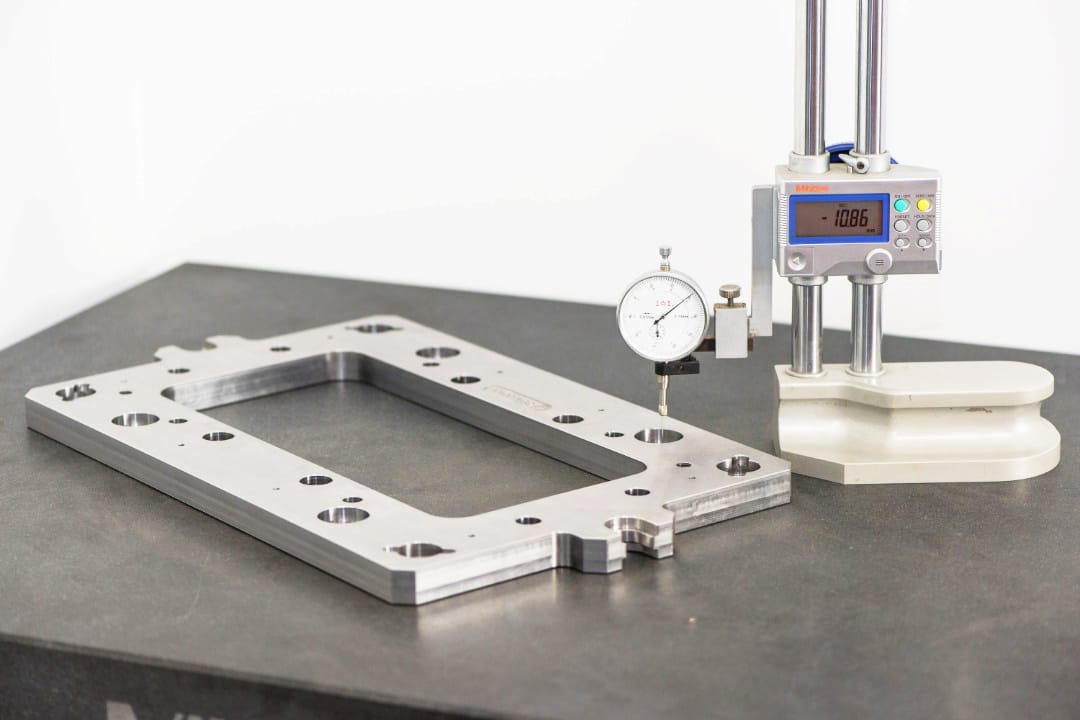

Qualitätskontrolle

F. Qualitätssicherung

Qualitätssicherung ist eine unserer wichtigsten Fähigkeiten. Unser Qualitätsmanagement ist prozessorientiert und umfasst das erste Produktdesign, die Entwicklung, ebenso wie das Programmmanagement und den Herstellungsprozess. Die Qualitätssicherung wurde eingerichtet, um eine Vielzahl von Kunden- und gesetzlichen Anforderungen in unseren Tätigkeitsbereichen zu erfüllen. Unsere Produkte und Maschinen werden mit vollständigen Dokumentations- und Prüfkontrollen geliefert.