Concept Development, Product Engineering, and Implementation

We bring your innovative concepts to life

We offer our development expertise if you:

Want to turn a concept into reality,

Redesign or improve your product,

Develop a prototype into a series-production product.

With our locations in Germany and China, you benefit from strategic advantages, optimized costs, high quality, and a stable supply chain—backed by over 15 years of experience in product development.

Before defining a prototype, our top priority is to fully understand our customers’ needs and long-term goals. Based on this, we develop clear objectives to guide your project through our development cycle to mass production

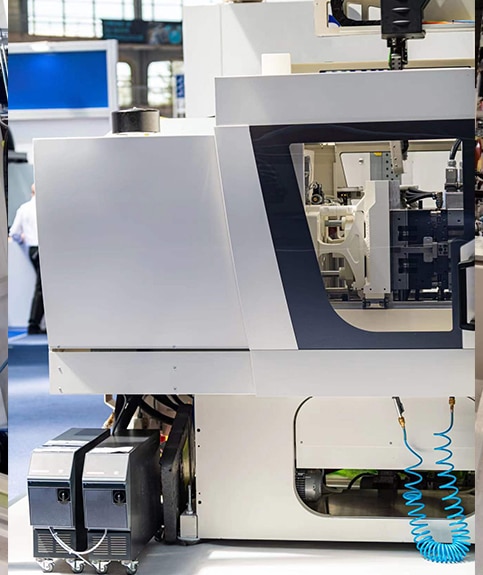

Machine design for manufacturing and assembly

We design and manufacture entire machines, including components for medium and large-scale machinery. Our services include:

Engineering & Design

Procurement

Project Management

Manufacturing

Modernization of Complex Systems

The machines we develop are durable, highly precise, and highly productive.

As a custom engineering client, you are involved in every phase of the project. We start with a consultation to define goals, scope, and specifications. Our engineers then design your machines, systems, or components based on your requirements. Once we finalize a design that meets your needs, our manufacturing team produces and assembles it using the highest-quality materials.

Our engineers have in-depth knowledge of various materials, strong technical expertise, and creativity. As a trusted and qualified partner, we support you throughout the entire project. Even after production, we continue to provide technical support whenever needed.

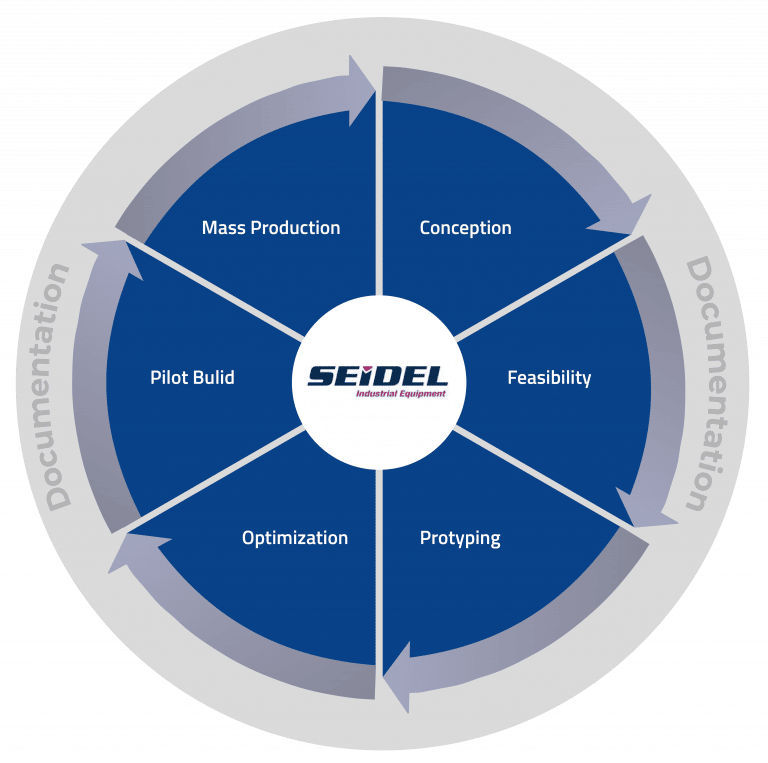

Product Development Cycle

The Seidel team stands out for its flexibility, offering solutions at various stages of your product’s development cycle—from initial concept to full-scale production.

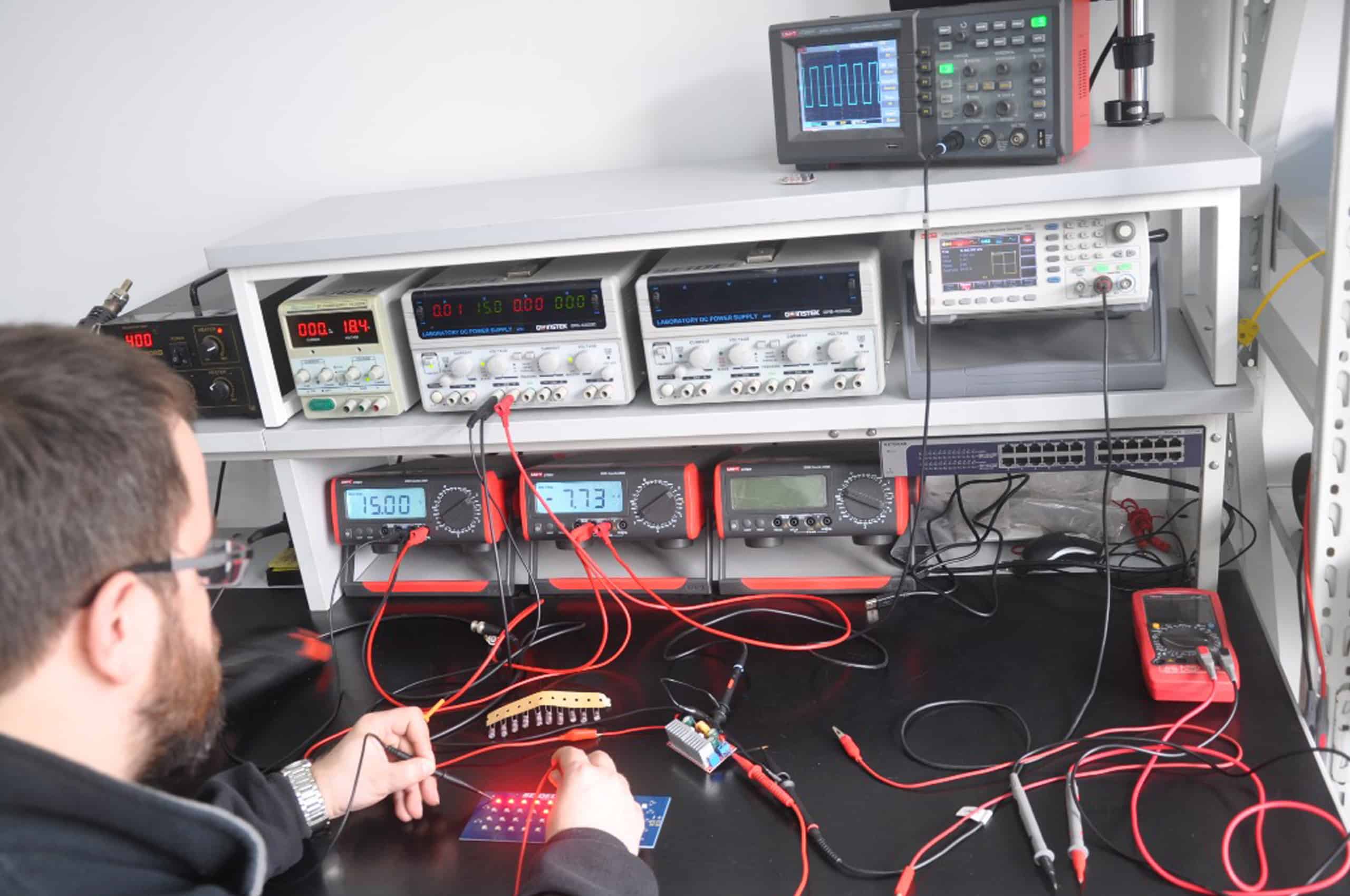

Proof of Concept Prototyping

Process Automation and Optimization

Product Prototype Design, Development, and Commercialization

Feasibility Testing and Analysis

Low Volume and Prototype Fabrication

Scaling Volumes with Designs for Manufacturing Assemblies

Where do you currently fall on the product development chart?

Every great product starts with an idea

Concept development is the first step in the product development process and typically the most comprehensive one. Based on our initial consultation and your defined requirements, we create a feasible and cost-effective concept.

Does it actually work?

The goal of a feasibility study is to determine whether a concept and its key components are practical and functional. During this phase, the original concept is refined, technology and scientific foundations are verified and optimized, and critical parameters are defined with variables and constraints.

We conduct initial tests, ensuring that the concept is both viable and ready for the next stages.

Creating a first prototype!

Once the concept has been validated and specifications are established, it’s time to bring it to life. This phase often requires iterative execution loops before achieving success. Seidel minimizes the number of iterations by thoroughly validating the technology and prioritizing functionality in the early stages of the development cycle. Functionality is the key to a successful mechanical product.

Better, faster, stronger, and less expensive.

We continuously develop new initiatives to enhance production efficiency. This includes optimizing quality, reducing lead times, and implementing cost-efficient strategies. Staying competitive is an ongoing challenge, but more importantly, it allows us to provide our customers with a decisive advantage in their market.

We Work out the kinks.

At this stage, test engineers and quality assurance teams step in to review, qualify, and validate various aspects of the project. The final prototypes serve as a “dress rehearsal” before full-scale production approval. This is typically the last opportunity to make any final design adjustments before launch.

Ready for release.

The moment everyone has been waiting for—the first full production run. At this stage, the design is finalized, drawings have been officially approved, and configuration control is in place. Robust quality assurance systems ensure that every completed unit meets customer expectations, industry regulations, and our own high standards. Production volumes have typically increased, final testing has been conducted, and all regulatory requirements have been met.